videos

Product Description

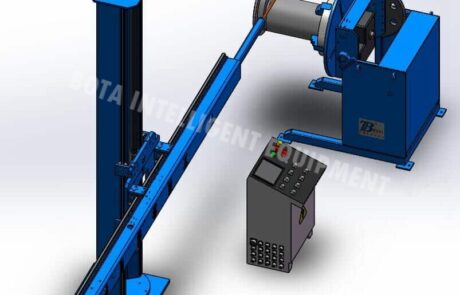

(1) BCZQ3×2m Electric rotary electric travelling welding column and boom

The main components of the equipment: Column, boom, lifting mechansim, walking trolley, rotary mechanism, lifting guide bracket, lock rails and other components. Its characteristics:

1、columns and beams are made of a whole box structure, High mechanical strength, good stability, compact structure. In the periphery of the base liner beneath the column increases, Fully guarantee rose to the highest post in the effective stroke, Deflection arm extends under the maximum effective stroke, And to ensure steel.。

2、manufacturing process using the first roll forming, then weld the web and rail way, Reduce weld seams, To improve the strength and appearance of the whole column, While reducing the HAZ, Reduce the damage of its own excellent properties of steel. After welding using to stress treatment, To ensure that the mechanical properties of the column。

3、After welding using special large planer processing rails, ensure the accuracy of the bracket walk。

4、together with the lift arm bracket seat is decelerating machine motor driven roller chain sprocket drive double to complete the work by lifting the top of the worm gear. To reduce the drive torque worm reducer, is installed in the column equilibrated with a counterweight, in order to improve cross-arm lifting stability and security, to enhance the use of worm gear reducer with self-locking worm gear。

5、Column rotation is the electric type, boom can be ± 180 ° rotation. Installed in the lower end of the column worm gear reducer drive rotation support to complete this task. Rotary bearing support comes with high precision external tooth type rotary disc, flexible rotation. Columns are manually locked。

6、the transverse boom telescopic using AC motor variable frequency stepless speed regulation, the starting torque is big, the speed is steady, the reliability is strong. Gear rack meshing transmission, high transmission accuracy, no crawling, no jitter。

7、for the V shape guide rail, post-weld stress relief by vibration aging. After planing, milling forming long life, good stability。

8、At the bottom of the welding column and boom equipped with the travel trolley, Trolley walking is electric walking, walking speed of 2000mm / min。

9、Welding column and boom is equipped with multi-functional hand-held, hanging operation box, you can operate boom movements, boom stretch, speed operation of the nose “X” axis “Y” axis trimming。

CO2-b Electric gas welding head

1) A pair of electric trimmer , a set of automatic welding wire head hanging , adjust the distance in the X / Y axis to ± 50mm, Can facilitate the welding torch on the weld.

2) The hanging gas welding wire head with the head of the overall rotation, deflection clamping mechanism, so that any deflection angle of the nose to meet the requirements of the inner seam welding;

3) Hanging gas welding wire feed head with planetary gear reduction system, wire feed torque, wire feeding stability, torch assembly with eccentric design, conductive performance, wire correction mechanism to ensure that the welding rod vertical;

OTC Microcomputer Digital Control CO₂ / MAG Welding Machine XD500SII (S-2)

Using high-performance microcomputer control, by changing the software program to change the arc characteristics, better meet the user needs of the arc characteristics of diversification. Welding conditions to adjust a wide range of high-speed welding excellent, significantly reduce the amount of spatter。

To achieve a complete unified regulation, constant penetration control function makes the operation easy

Optional unique flow limiting program to achieve on-site welding quality management (XD350SII / 500SII use)

Thyristor overcurrent protection function makes the performance of the welding machine more reliable

Remote control box and wire feeder integrated design, operation more convenient

Current and voltage digital display, more intuitive

solutions

Our products are mainly used in manufacturing, construction and energy industries. In the manufacturing industry, they are widely used in the manufacture and maintenance of large metal structures such as ships, bridges, pressure vessels, pipelines and storage tanks. In the construction industry, they are used to build large buildings, steel structures and bridges, etc. In the energy industry, they are used in oil and gas pipelines, petrochemical plants, nuclear power plants, etc.

We can provide the most suitable equipment and services according to your specific needs and specific application scenarios, helping you to improve production efficiency and reduce production costs.

about us

Luoyang Bota Intelligent Equipment Co., Ltd. is a high-tech enterprise that integrates research and development, manufacturing and sales of professional intelligence in automatic welding and cutting of equipment. Our company has been certified by GB/T19001-2016/IS09001:2015 for its quality management system and European Union CE certification. With the developed heavy industry in manufacturing and processing base, our company has now become the leader in the welding and cutting industry in the country. Our products have been distributed all over the country and have been exported to Europe, America, Southeast Asia and many other countries.